Laminated Glass

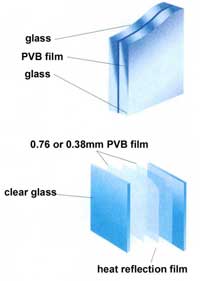

Laminated glass is a kind of safety glass which is combined from one or more layers of PVB through heating and pressing processes by autoclave. On order to satisfy the requirements of different customers and designers, we're able to provide milky white or multi-cool, films and films with geometrical patterns other than transparent PVB for customers' selection.

Laminated glass can be widely applied in houses, net racks, canopies, point-supporting curtains walls, observation elevators, airports, counter of bank and windows of motor, etc.

features of laminated glass:

1. High safety performance: PVB film is firm, rich of adhesion and cannot be penetrated when impacted. Therefore, even when the laminated glass is broken, the sheet glasses are still able to adhere to PVB films and thus the persons and things around won't be hurt;

2. Good sound insulation performance: PVB has good damping action on sound waves; therefore, the laminated glasses are able to block the transmission of sound effectively and reduce the noises obviously;

3. Ultraviolet radiation prevention: Besides ensuring the visible lights are able to enter indoors, PVB films are able to block 99% ultraviolet radiation and prevent the furniture and other items indoors from discoloring due to irradiation of ultraviolet radiation.

4. Defense to hurricane and earthquake: Due to rupture or fracture in laminated glass, debris remained in situ performance, it causes people in hurricanes and the earthquake zone are pleased to use the materials.

5. Bullet-proof, anti-riot: excellent toughness of PVB, laminated glass in fierce attacks by foreign forces, films will absorb a large amount of impact properties to make it so quickly decay, PVB films by increasing the thickness of glass or a combination of laminated glass effectively prevent bullet-proof from attacking.

6. Sun control characteristics : laminated glass (especially color laminated glass), can reduce the transmission of sunlight, thereby lowering the energy consumption of refrigeration. While weakening sun glare without causing color distortion.

7. Water pressure-resistant: not only laminated glass have a certain intensity, but have good water-resistant when its compatibility with the surrounding glass sealed plastic closure.

Dimension of laminated glass

Max. Size: 2500 MM X 6500 MM

Note: the dimension of lamination is subject to the size of heat bending glasses.

Thickness of Original Sheet: 3 ~ 19mm

Total thickness of laminated glasses: 6.38-300mm

Color for PVB film:clear, cream white, gray, blue, green, pink.

Thickness of PVB film: 0.38 ~ 2.28mm.

Types of laminated glass:

Types: Ordinary transparency and color laminated, coated & laminated, tempered & laminated, Low-E laminated, arts laminated, heat bending laminated, as well as bullet-proof glass and laminated glass and aquarium glass.

Application range of laminated glass:

1. Building windows and doors, curtain walls, ceiling lighting, skylights, ceiling and overhead ground, the large glass wall, indoor glass partition, glass furniture, shop windows, counters, the use of glass aquarium, as well as almost all occasions to use glasses.

2. Security windows, bullet-proof, explosion-proof tent with lighting, glass roof, banks, automobiles, such as underwater construction or interior decoration.

Quality Control:

Conformity to GB9962-1999 " the National Standard of Glass"

In line with ANSI297.1 USA Standard

Production ability of laminated glass:

The corporation has a standard, high level of automation, production environment (temperature, humidity, Cleanliness) control system, advanced laminated glass production equipment and technology equipment. PVB used for the import of raw materials and high-quality float glass, with an annual output of 280,000 square meters of high-quality laminated glass series products.

laminated glass

laminated glass