Flat / Bent Tempered Glass

Toughened glass is manufactured through cooling the surface of glasses rapidly and making the compressive stress distribute in the surface of glasses and the tensile stress in the central layer when the sheet glass is heated near the softening point. Because the tensile stress produced by the powerful and even compressive stress is counteracted by the powerful compressive stress of glasses, the safety of glasses is improved.

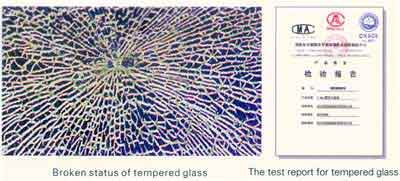

The strength of toughened glass is about eight times of that of the common glasses, i.e. more than 95 Pa. If met with by powerful external force, the toughened glasses will be broken into particles as small as bean. Thus, its harm can be reduced. Toughened glasses can be widely applied to building decoration, furniture, vehicles and vessels.

Tempered Glass Features:

Safety: After broken, the toughened glasses will be broken into particles as small as bean. Thus, the possibility of its harm to body can be reduced.

High Strength: impact strength and flexural strength of the same thickness of toughened glasses is generally 4-5 times as strong as the common glasses.

Hardness: 3~4 times of that of the common glasses.

Thermal Stability: with good thermal stability, to be able to withstand the temperature of the glass is three times as big as the common ones, and 300 ° C temperature changes can bear.

Application: Toughened Glass is of safety glass, which are widely used for higher mechanical strength and safety of the premises. Such as: glass doors and construction curtain wall, the establishment of a window, indoor partition, fixture, partition for the location of near the intense heat and the impact severed by the hot and cold.

Tempered Glass Dimensions:

Max. Size: 2440 MM X 3660 MM

Min. Size: 300 MM X 300 MM

The Range of Thickness:

Toughened glass 4 MM ~ 19 MM

Tempered Glass Type:

Coated Glass, Pattern Glass, glazing Glass, and Glass Sheet in various colors.

Usage Range of Tempered Glass:

1. construction curtain wall

2. glass doors & windows

3. Support bar of Staircases & escalators

4. Different types of the glass art decorations

5. location of near the intense heat and the impact severed by the hot and cold.

Quality Control:

Conformity to GB/T9963-1998 "the National Standard of Toughened Glass" With ASTM1048-97 USA Standard.

Test Report:

Spontaneous explosion of tempered glass is a difficulty that has been overcome yet. In order to reduce the spontaneous explosion rate, the company has introduced homogenous furnace of toughened glasses, which is able to reduce the probability of spontaneous explosion and improve the safety performances of products.

Points of attention:

1. Seen from certain direction, you may find slight irregular light, which are just the characteristics of heat treatment glasses.

2. Before heat treatment, the glasses should be cut to the required dimensions, punched and grinded edges. After heat treatment, cutting or edge grinding is not permitted.

Production Ability of Flat / Bent Tempered Glass:

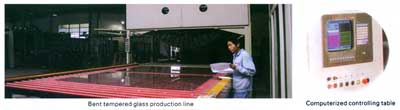

In order to realize scale production and improve the quality of products, the company has introduced a large horizontal glass toughening equipment from TUNGLASS. Furthermore, in order to satisfy the requirements of architectural images, the company has introduced a bent arc toughening production line to manufacture arc toughening glasses.

The technical performances of toughened glass comply with American ANSIZ-97: standards of glasses for building industry and European ECER-43: standards of glasses for motor industry. The company is able to manufacture common-shape, abnormal-shape and peculiarly abnormal-shape toughened glasses.

Large horizontal tempered glass production line

Bent tempered glass production line